FORGED SERIES

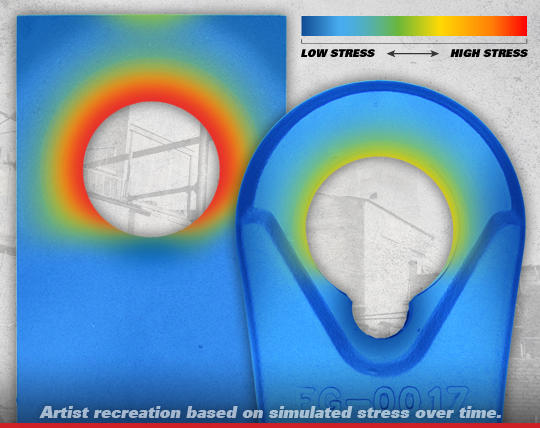

- Reduce Hole and Rod Wear: Achieve greater durability over castings with our forged hammer mill hammers! Our forged series is proven to consistently reduce rod and hole wear. Created with a thicker shoulder than a standard hammer, our forged series allows more contact area between the hole and rod, resulting in a reduction of stress between the two.

- Mass Where it Matters: Our hammers are engineered to concentrate mass where it matters — around the hole and strike end.

- Prevent Hammer Lock: Standard on all forged series hammers, the notched relief hole improves performance by reducing the likelihood of hammers becoming locked on the rod. The relief hole easily releases built-up material during operation.

Customizable

![]() The G3 forged series is customizable to fit your unique application. They are available in a variety of swing lengths, and three different strike end styles: 1/4", 1/2", and G2 (2 1/4" blades).

The G3 forged series is customizable to fit your unique application. They are available in a variety of swing lengths, and three different strike end styles: 1/4", 1/2", and G2 (2 1/4" blades).

![]() Swing lengths can range anywhere between 6.5" and 9.25" from the center of the rod hole. Does not apply to 0.5" and G2 forged hammers.

Swing lengths can range anywhere between 6.5" and 9.25" from the center of the rod hole. Does not apply to 0.5" and G2 forged hammers.

INNOVATION NOT IMMITATION

Forging Process

The forging process compresses steel into high-strength parts that are able to withstand abuse without failing. For this reason, forged parts often replace castings in the applications where reliability and safety are critical. We control the chemistry of steel produced by the mill, and certification must be verified by our engineering department before it is ever used.

Precision Machined

Every forged shoulder is checked to ensure a tight tolerance is maintained — and any outside our range is precision-ground to tolerances thinner than a strand of hair. Once an order is placed, forged series hammers are precision-drilled to the customer’s specified swing length.

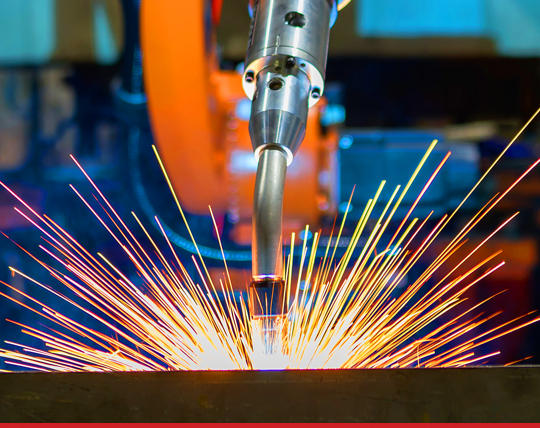

Duraweld Hard Facing

Our proprietary hard facing process utilizes state-of-the-art welding centers to produce a consistent high-crown hard facing on every part. Hard facing can be customized to the customer’s unique application.

ADDITIONAL SERVICES

Re-patterning

All forged series orders include re-patterning of the customer's hammer mill to account for the forged hammer’s thicker shoulder — at no additional charge!

Precision Balancing

Orders are balanced to ensure minimal vibration during operation, saving our customers time and money by preventing unplanned shutdowns due to vibration.

Pre-Assembly

Increase your uptime with our pre-assembled pockets. Each pocket is packaged to your specific mill pattern, cutting installation time.

Expedite Service

When things don't go according to plan, reduce downtime and keep your system up and running with expedite service on all products — even if you’re not a current customer. Utilizing our Expedite Service, our industry-leading processes allow us to take a new set of hammers from drawing to shipped in three days for the majority of mills.